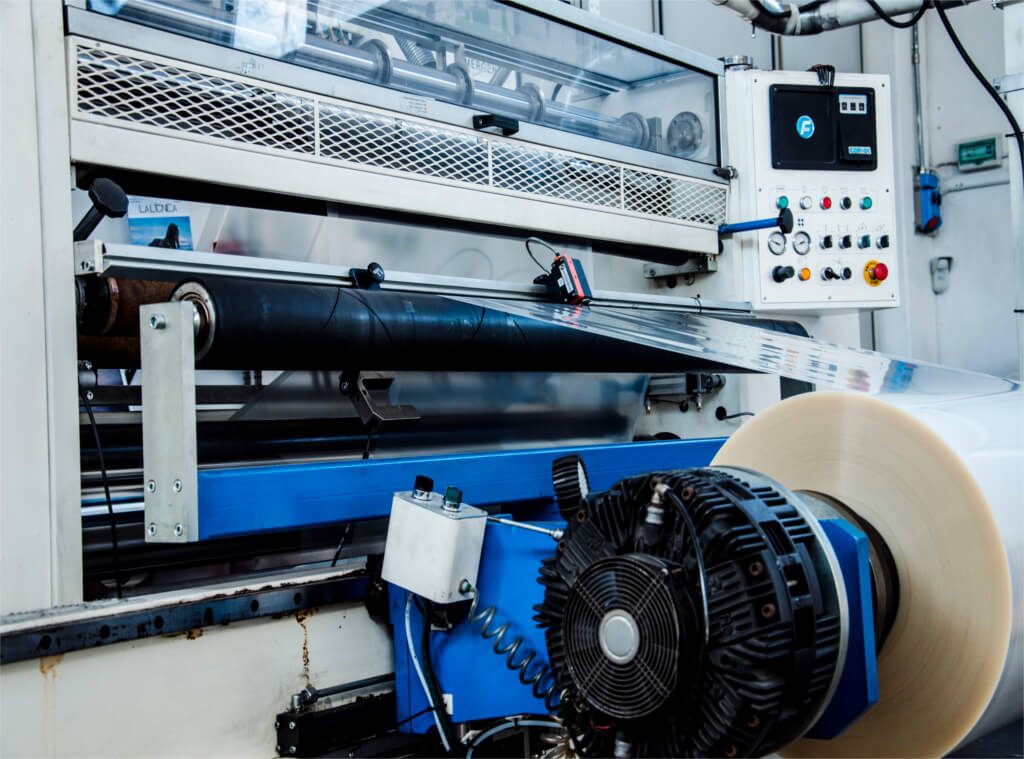

Our company uses its own production process using flexo printing machines using latest generation digital printing systems , solventless laminators and rewinders. The machines are equipped with in-line quality control and are able to monitor / control and detect any anomalies that do not comply with the previously codified production standard at any time during production. In addition to these we use external instruments such as digital microscopes (for print quality), densitometer and a spectrophotometer , for continuous color control and ensure repeatability of the work over time.

Our company transforms and sells plastic and paper films suitable for food and non-food packaging starting from the most common single-layer materials up to multi-layered technical materials and applying the most modern flexographic printing technologies to produce the most suitable packaging for all types of products.

In addition we carry out printing, laminating and cutting on behalf of third parties.

The families of materials

The main materials used are:

- Polypropylene (pp)

- Politene (pe)

- Polyester (pet)

- Nylon (opa)

- Aluminum (alu)

- Cellophane

- Paper

- Biodegradable & compostable

Of course, each of these families contains in turn a multitude of specific materials suitable for packaging machines and the type of packaging required (packaging in high speed low welding, barrier, in ATM, vacuum, pasteurization, etc.). To see the field of application of our productions we ask you to visit our page ” Application field ” in the menu bar or click here.